Project 11

EXPLORING electrospinning as an advanced manufacturing technology

(prof. kevin walsh & Dr. Dilan Ratnayake, ECE Dept.)

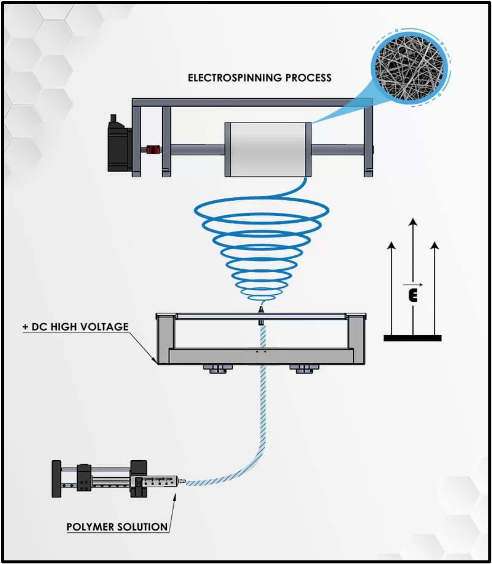

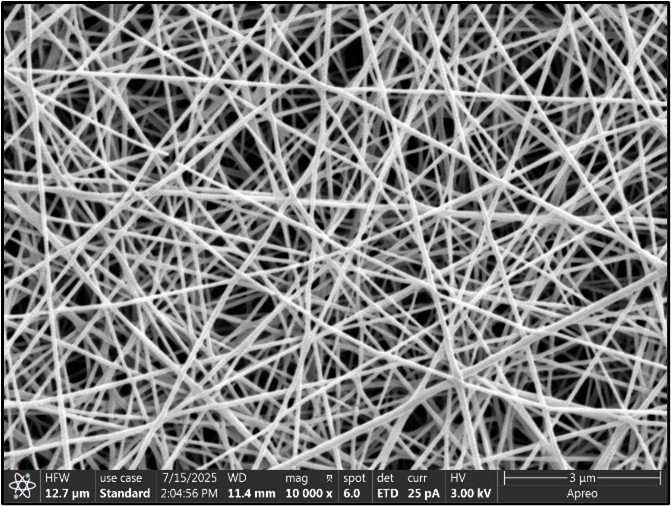

Electrospinning is a relatively new advanced manufacturing technology that uses a high voltage to produce nano-meter sized fibers using an accurate needle-dispensing system in a well-controlled environment. Electrospinning can be used to produce ultra-thin polymer nanofibers for applications in the biomedical, filtration, textile, and wearable research fields. It has many manufacturing advantages, including low-cost, simplicity, and scalability. In this REU project, the student will first learn about the physics and intricacies of the electrospinning processes. Then he/she will learn how to independently use the University of Louisville’s new Inovenso NE300 commercial Electrospinning System. Finally, the student and mentor will carefully select a polymer material and characterize it for electrospinning and a specific application. Parameters to be examined include molecular weight, working distance, voltage, and dispensing rate. Nanofiber morphology (fiber diameter, uniformity, beading, porosity, etc) will be characterized using Scanning Electron Microscopy (SEM).