Project 9

Bioceramic-Based Biomaterial Products for 3D-Printed Orthopedics

(Prof. KUnal Kate, ME)

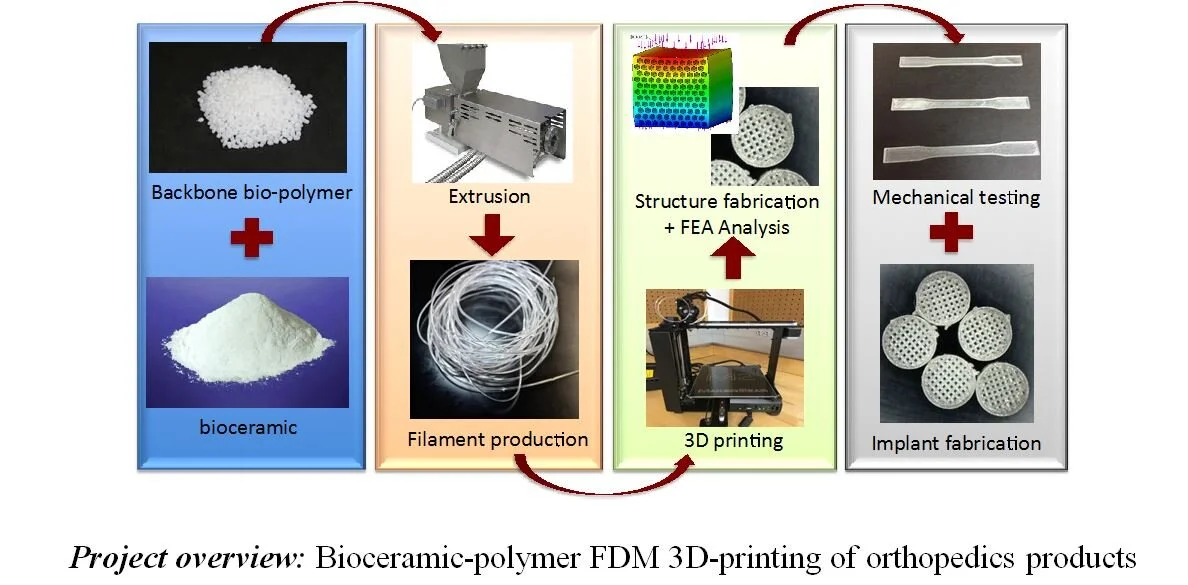

Fused deposition modeling (FDM) 3D printing is currently possible with various thermoplastic polymers such as polylactic acid (PLA), polypropylene (PP), polycarbonate (PC), or acrylonitrile butadiene styrene (ABS) for different applications. However, we currently limited materials available for 3D printing of orthopedic implants that have mechanical properties similar to natural bone (1.8-2.1 g/cm3). There is a need in orthopedic surgery for strong biocompatible implantable materials for fracture fixation. Because fractured bones heal completely, it is often desirable for orthopedic trauma implant materials to dissolve or reabsorb over time so they do not need to be removed in a second surgical procedure. This project focuses on the FDM 3D printing of orthopedic products from biodegradable polymeric blends of polylactic acid (PLA), and polyethylene glycol (PEG) with bioceramics such as hydroxyapatite (HA) and bioglass (BG). The project theme is described in the Project overview below. Initially, filaments will be extruded for various percent loading of bioceramics in the polymer matrix, and tensile coupons will be printed with various internal structures and tested for mechanical strength and compression to get the required structural, mechanical properties and micro-textured surface that are required for specific orthopedic products. Finally, target geometries of clinical relevance with different internal structures will be 3D printed from the developed filament and evaluated for their suitability to resist impact by studying load-bearing properties. If successful, this project will lead to create an array of 3D printed orthopedic products with wide range of mechanical properties, micro-textured surfaces, and structure for regenerative medicine.